by Gary Stevens

Part one of two: Line types and premature damage

In this two-part series, we’ll dive deep into the world of canopy maintenance – another crucial aspect of keeping your kit in top-notch nick. Think of your canopy like a beloved sports car: to purr, it’s going to need your care and attention.

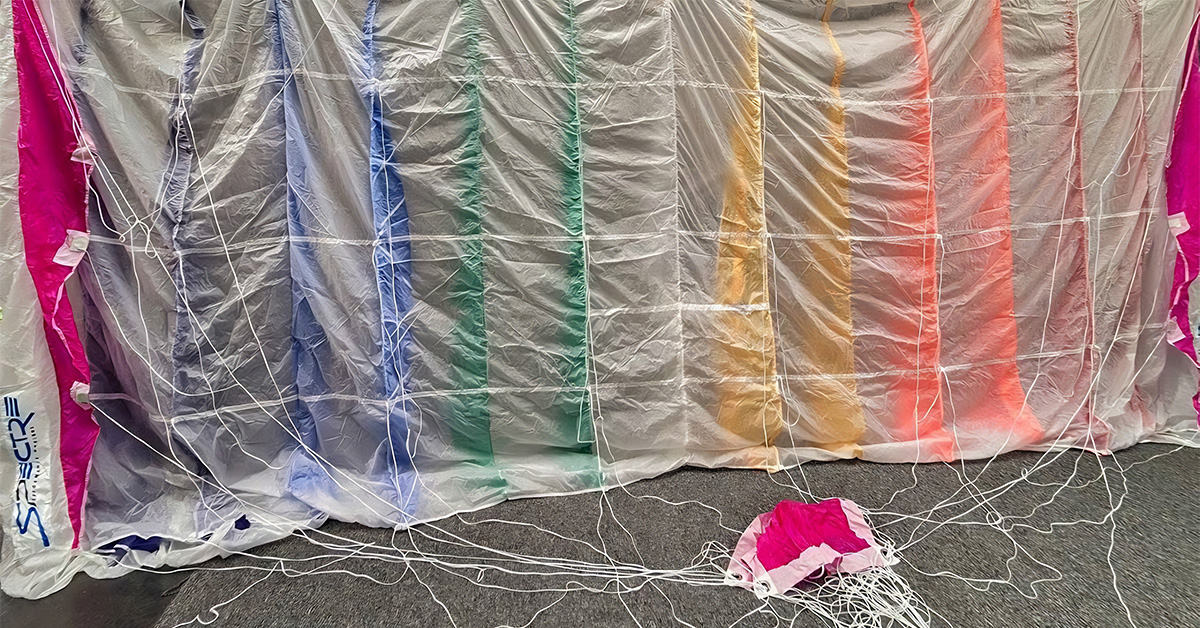

In this first installment, let’s unravel the mysteries of parachute lines (and the potential damage thereof that could compromise your safety in the skies).

Line Types: The Good, The Bad, and The Stretchy

I’ll start us off with a caveat: This subject is very subjective and open to personal opinion. You can easily get yourself stuck in a line-related rabbit hole if you’re not careful. At the end of the day, though, most people agree that the type of line we select for our particular canopy depends on the canopy’s size, its performance, and the discipline for which it will be used.

There are four main types:

Dacron: The Forgiving Veteran

Colour: Typically, white

Pros:

- Maximum elasticity, making it a nice choice for students, tandems and seasoned jumpers worried about hard openings

- Easy on the ol’ bod during deployment

Cons:

- Abrades easily

- Bulky design means you might need to drop a canopy size to fit it in your container

Microline: The Tough Cookie

Colour: White

Pros:

- Incredibly abrasion-resistant

- My personal recommendation for canopies 150 square feet and above

Cons:

- Prone to heat shrinkage

- Gradual performance loss (so subtle you might not even notice)

Vectran: The Stable Performer

Colour: Cream (also available in orange and black)

Pros:

- Dimensionally stable

- Maintains line trim beautifully

Cons:

- Poor wear properties

- Best suited for canopies 150 square feet and smaller

HMA: The Compact Contender

Colour: Predominantly cream, but also available in orange and black

Pros:

- Softer and smaller in diameter for the same load specification

- Takes up less space in the pack

- Dimensionally stable

Cons:

- Abrades fairly easily

Line longevity

Here’s a golden rule: a typical line set will last around 500 jumps, with brake lines needing replacement at about 250 jumps. But – and it’s a big but! – this depends on:

- The environment the lines are jumped in (as sandy, dusty landings wear lines faster)

- The lines’ load rating (typically 750 pounds, with brake lines at 1,000 pounds)

Premature Damage: The Silent Killer

While, unfortunately for us, canopies do wear out over the seasons, there are a few culprits that can cause canopies to age out decidedly before their time. Let’s avoid those. Here’s how.

Sun and sweat

Contamination is probably the biggest problem that our nylon faces. The main cause of this contamination is twofold: sun damage and sweat. This dynamic duo of destruction really takes its toll. A breakdown of the fabric’s coating can quickly lead to nylon degradation. At first, the coating on the fabric starts to break down, then eventually the nylon itself.

To spot it, look out for fading, especially on the centre cell’s top skin. Pro tip: wear a T-shirt when packing and keep your gear out of direct sunlight.

Slider grommet and bridle damage

Those metal grommets move fast and hit hard during the course of any given deployment – and they’re hell on fabric.

Check the centre top skin of the canopy near and around the tail for damage. Are you seeing tiny pin pricks around the warning label? These are typically caused by sharp edges on the bridle and are easily fixed by a rigger. If there’s a lot of damage in this area, or if the damage begins to run together, the canopy should be patched.

Cross-port vent fraying

Cross-port vent fraying and line burn are really the last of the major damage that we have to worry about (providing we don’t tear the parachute on a door handle, or a barbed wire fence).

Have a look inside your parachute and inspect the cross-port venting to make sure that the ports are in good condition and haven’t ripped or torn.

Line burn

If you’re suffering from a case of line burn, you’ll know it: the long, straight burn marks are easily identifiable. In the worst cases, the line will cut through the fabric, and it’ll have to be repaired by your rigger.

Line burn, like many maladies of the nylon, can be prevented by paying attention during packing.

Stay tuned for part two, where we’ll get into the intricacies of links and slinks!